The power of additive manufacturing beyond energy

The global technology leader supplying customers with training, design, manufacturing, and project execution for high performance additively manufactured parts.

Innovation in every layer

At Material Solutions, we’re at the forefront of Additive Manufacturing (AM), completely revolutionizing how we design, produce, and even repair industrial components. We utilize sophisticated 3D printing technologies like Laser Powder Bed Fusion (LPBF) and Wire Arc Additive Manufacturing (WAAM) to develop high-performance parts, facilitate rapid prototyping, and offer on-demand spare parts. This significantly cuts down on both lead times and material waste. Our expertise also extends to advanced engineering services, including the design, simulation, and qualification of AM components. We’ve built this knowledge on over a decade of experience and millions of operating hours of AM parts within our own gas turbine fleet.

Our Expertise in Metal 3D Printing

Additive Manufacturing Services

Training & development

Empowering your team with foundational to advanced AM knowledge.

Design & consulting

Optimize your designs for additive, guided by industry-leading specialists.

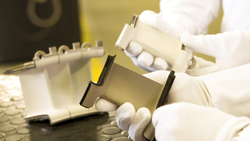

Part manufacturing

From prototypes to production, leveraging advanced in-house technologies.

Our journey in additive manufacturing

Today, our AM capabilities go beyond prototyping; we’re actively engaged in serial production of complex parts like turbo housings, burner nozzles, and turbine vanes, which have drastically improved lead times and provided previously unattainable levels of performance. We use advanced repair and upgrade solutions for power generation assets to reduce scrap and increase the sustainability of Siemens Energy parts.

Why Material Solutions for Additive Manufacturing?

Advanced post-processing capabilities

Heat treatments, conventional and non-conventional machining, welding, brazing, coatings, and more.

Industrialized AM production

With over a decade of expertise and a million+ part operating hours.

Integrated design-to-print-to-part solutions

For full-lifecycle services, including DfAM optimization and serial production.

Accelerated AM adoption

Through advanced training, rapid prototyping, and high-performance component innovation.

Certified supplier

ISO9001, AS9100, ITAR Registration, NadCap, AMS7003

Unlock new possibilities with additive manufacturing

Prototyping

Material Solutions additive manufacturing accelerates the innovation cycle for industries like aerospace, power generation, oil & gas, and automotive through advanced prototyping. We enable engineers to swiftly create and rigorously evaluate new part designs, allowing for rapid iteration and refinement of concepts in record time. By quickly transforming digital models into physical prototypes, we empower faster design verification and testing, significantly shortening product development timelines and ensuring that solutions are optimized for performance and reliability before committing to full-scale production.

Repair

Additive Manufacturing revolutionizes asset longevity and operational efficiency through advanced repair solutions for critical components in industries like power generation, oil & gas, and industrial manufacturing. Utilizing sophisticated additive repair techniques, we can precisely rebuild worn or damaged parts, extend their service life and significantly reduce the need for costly replacements. This capability minimizes downtime, optimizes maintenance schedules, and enhances the sustainability of high-value industrial assets, ensuring continued reliable operation in challenging environments.

Production manufacturing

We offer comprehensive additive manufacturing capabilities for high-performance component production across demanding sectors such as power generation, aerospace, performance automotive, industrial, and defense. Leveraging advanced metal additive processes like Laser Powder Bed Fusion and Wire Arc, we produce materials with superior strength and productivity through optimized build parameters. Our quality assurance and post-processing ensure that every manufactured part meets the standards required for critical applications, from turbomachinery components to specialized tooling.

Spare parts on demand

For sectors heavily reliant on operational continuity such as power generation, aerospace, and industrial applications, Material Solutions additive manufacturing provides agile „spare parts on demand“ services. This capability drastically reduces lead times for critical spares, eliminates the need for extensive physical inventories, and mitigates supply chain disruptions. By leveraging digital blueprints and additive manufacturing, we can produce high-quality, certified replacement parts precisely when and where they are needed, ensuring maximal uptime and operational resilience for even legacy equipment.

Advanced AM technologies in-house

Powder bed fusion

Powder bed fusion is an advanced additive manufacturing process that uses a heat source, such as a laser or electron beam, to selectively melt and fuse powdered material layer by layer, creating a solid 3D object. This technique can produce complex geometries with high precision and is used for metal parts. PBF includes various methods like Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM) utilizing different energy sources to achieve fusion.

Wire arc additive manufacturing

Wire arc additive manufacturing is an advanced 3D printing technique that combines Gas Metal Arc Welding (GMAW) with advanced robotics to create large, complex metal parts. Using an electric arc to melt and deposit metal wire layer by layer, WAAM is known for high deposition rates, cost-effectiveness, and the ability to produce parts over a cubic meter in size. It offers reduced material waste, lower startup costs, and the capability to manufacture parts with complex geometries and multiple materials, making it ideal for engineering structures and component repairs.